What is Foam Prototyping & Foam Modeling?

- Sigal Barnea

- Mar 9, 2020

- 2 min read

Updated: Sep 17, 2024

A foam prototype or a foam model, not to be confused with rapid prototyping which is 3D printing application, is a great way to show customers the product being developed, from the idea stage to the processing phase, prior to the finished product.

It is a good tool since it can reveal design flaws that might not have been detected in the 3D CAD file had we went straight to production. It also gives us a realistic preview of the design scale.

It is always a good idea to present the customers with a few rough foam models and prototypes, so that they can evaluate and make the changes needed to the design and/or the material used prior to fabrication of the final product.

The foam prototype / model, being a foam version for whatever purpose we need, can save us a great deal of money in development and reduce the marketing time.

The prototype, mostly being a 3D shape is typically CNC machined from a CAD date file on a CNC router, using materials such as EPS (Expanded Polystyrene), XPS (Extruded Polystyrene), EPP (Expanded Polypropylene), PE (Polyethylene), PU (Urethane tooling foam), Renshape, EVA, MDF, as well as plastics, acrylics, wood and aluminum light metals.

Once machined, the prototype can either be left in its raw foam state or can be hard coated and/or painted as needed. If a more realistic look is required it can also be hand carved, and graphics, labels and stickers can be added

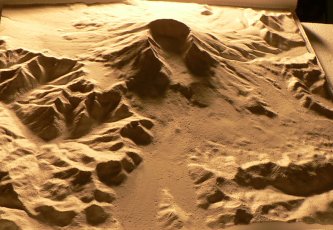

Foam prototyping and modeling can be applied to a small or a regular size product, but also for large-scale ones, including vehicles, aircrafts, boats, architectural models and landscapes, topographical maps, large theme park characters, theaters and movie large props, museum exhibits, sculptures and statues. It is imperative for all manufacturing industries, especially for automotive, Aviation & Aerospace, Marine, Industrial Equipment and Medical.

AND, If the model required is of a large-scale, it can be machined in pieces then glued together as a whole unit.

#prototype #prototyping #foam #machining #foammodeling #CNCprototyping #EPS #XPS #EPP #urethane #toolingfoam #polyurethane #EVA #MDF #3Dprinting #foamprototype